Well now we have some working wheels, its time to make a chassis and connect those wheels to it! It seems to me that in the RC space there have been some very successful large vehicles so I am going to save myself some headache and borrow some components to get my robot up and running the way I want it.

I went down to my local RC shop (I am so glad some still exist!) and bought a bunch of parts that are from a Traxxis XMAXX.

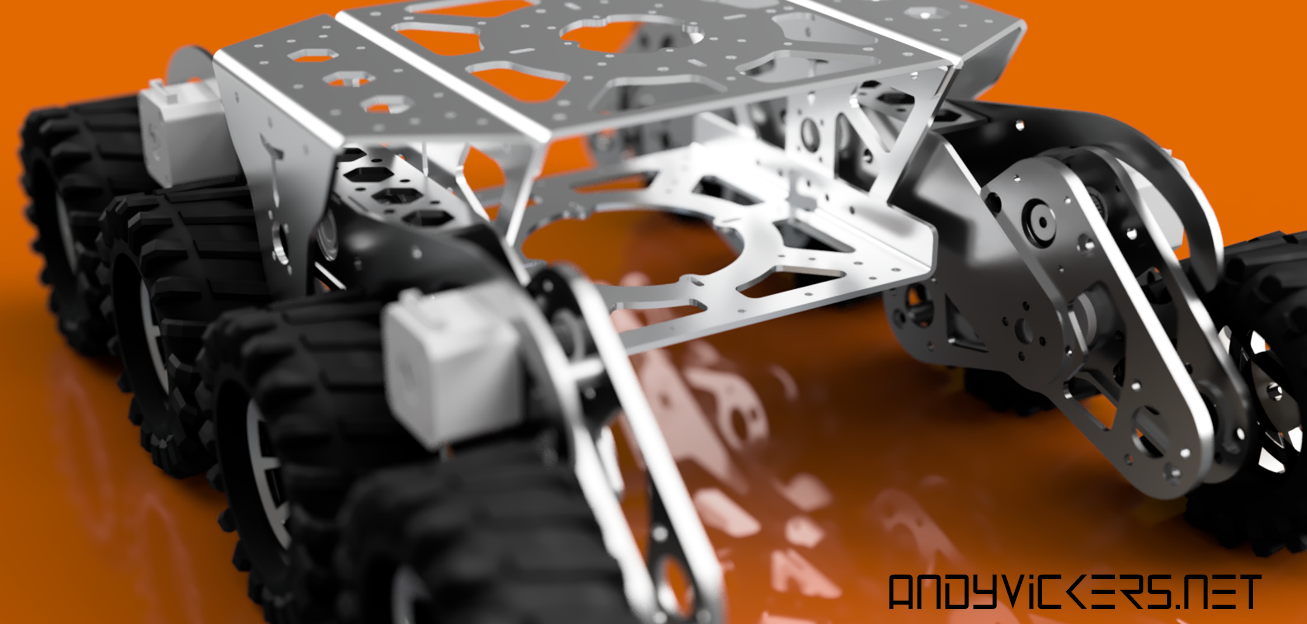

Well this is the biggest suspension I could find! but I looking at it all laid out, I am not sure if I went too big! lets try and design some components in Fusion 360 to make all this work and see how it looks.

Well … this isn’t a disaster! I have working suspension at least. I think the next thing I should do is mount my wheel hub. You’ll notice that I actually bought an RC motor to replace my stepper for some testing and hooked up an RC controller in the next video, but I will talk more about motors in another post as I have learned a lot already.

Well I did manage to connect my wheels to my suspension – CHECK!

what gives me pause at this point is that the motor seems to have two modes, FAST and CRAP ITS GONE THROUGH THE WALL. this is a limitation of RC type motors, they are built to just dump battery into motors without much thought for control. where steppers can be controlled very tightly by altering the angle, RC motors you do not have that ability. This was a learning on my part and so I either need to slow it down, or do something else. I think I need to think about this and come back to it.